FOAM MATERIALS

Following on from my short description of the

fabrics available to modellers we now switch our attention to

foam. Foam is used in two ways; either for the cores material in

wood veneered or glass vacuum bagged wings or as the sandwich

material for the skins of hollow moulded wings. We've all come

across white and blue foam but there are some other foams we

could look at...

Following on from my short description of the

fabrics available to modellers we now switch our attention to

foam. Foam is used in two ways; either for the cores material in

wood veneered or glass vacuum bagged wings or as the sandwich

material for the skins of hollow moulded wings. We've all come

across white and blue foam but there are some other foams we

could look at...

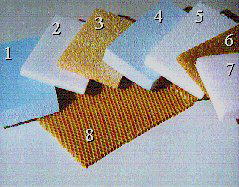

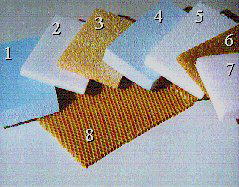

1) Styrofoam SP, 2) Rohacell 51,

3) Conticell, 4) Styrofoam IB, 5) De-Q-cell, 6) Termanto, 7)

Polyfoam Plus and 8) Nomex Aramid Honeycomb.

POLYSTYRENE

FOAMS

Polystyrene foams come in two types:

expanded foam and extruded foam. Common bead-type white

polystyrene is expanded foam (in a mould) and it's the cheapest

available. It comes in a variety of densities from about 17 kg

per cu. m. upwards for the large bead foam. Expanded foams are

only really suitable for covering with wood veneer since the fine

trailing edge needed for vacuum bagged wings is hardly obtainable

with this foam. There are, however, better white foams other than

the standard builder's yard material in DIY stores. Left to right

the samples here are:

One such PS foam is De-Q-cell found in Germany

which has a sort of crystalline appearance when you look at it. I

haven't seen it for sale here in the UK but it maybe available

from Windsurf board manufacturers, I don't know. It comes in 3

weights: 17, 30 and 40 kg/cu.m.

One such PS foam is De-Q-cell found in Germany

which has a sort of crystalline appearance when you look at it. I

haven't seen it for sale here in the UK but it maybe available

from Windsurf board manufacturers, I don't know. It comes in 3

weights: 17, 30 and 40 kg/cu.m.

Extruded polystyrene

(forced through a die) foams are eminently more suitable for wing

cores - their closed cell structure (hit the DOW logo to see it)

giving a much finer trailing edge. In the UK we call it Blue

foam, in France they call it Roofmate. It doesn't have

to be blue, of course for I have seen Gray board from

the States, an orange one from Germany and I'm told you can even

buy a green variety from the Bricolage at the Calais

Hypermarket. An old DOW catalogue I have actually lists 17 types

of Roofmate, Wallmate, Floormate boards with densities from 28 to

45 kg/cu.m. The one I generally use is called Styrofoam IB with a

density of 28 kg/cu.m. but I have also used Styrofoam SP

(34kg/cu.m.) which I found less easy to use.

Extruded polystyrene

(forced through a die) foams are eminently more suitable for wing

cores - their closed cell structure (hit the DOW logo to see it)

giving a much finer trailing edge. In the UK we call it Blue

foam, in France they call it Roofmate. It doesn't have

to be blue, of course for I have seen Gray board from

the States, an orange one from Germany and I'm told you can even

buy a green variety from the Bricolage at the Calais

Hypermarket. An old DOW catalogue I have actually lists 17 types

of Roofmate, Wallmate, Floormate boards with densities from 28 to

45 kg/cu.m. The one I generally use is called Styrofoam IB with a

density of 28 kg/cu.m. but I have also used Styrofoam SP

(34kg/cu.m.) which I found less easy to use.

Polyfoam Plus, the pink

extruded variant, available in the UK from LinPac, is once again

an insulation material for building which boasts the use of steam

instead of CFC's (Freon?) as the blowing agent. Its

cavity wall board has a density of 20 kg/cu.m. while the

floorboard comes in at 27 kg/cu.m. Lighter but a little more care

needs to be taken because it's easier to damage its surface

through heavy handedness and workshop dings. Cuts OK though with

a standard hot wire set up.

POLYMETHACRYLIMIDE

FOAM

Otherwise known as Rohacell (PMI) foam, this is a comparitively expensive white coloured foam.

It apparently does cut with a hot

wire like polystyrene foam although it is often cut with a knife or saw. It is

available in ready cut sheets at 1 mm, 2, 3, 4.... up to 65 mm thick and more. Modelling applications require 1 or 2

mm thick sheets. Its superior

compressive strength over PS foams means that it's ideally suited

for sandwich construction. Modern moulded models (especially

tailplanes) may use Rohacell as the sandwich between lightweight

(40 -70gsm glass or 100gsm carbon) plies of reinforcement cloth.

It can be cut and sanded easily and is not subject to attack by

most solvents (styrene, acetone, MEK, etc). Rohacell is made by

Röhm of Germany as is classified as Rohacell 31, 51, 71, 110,

170, 190, the numbers denoting it's density in kg/cu.m. We would

use the 51 type for modelling. UK suppliers are EMK plastics I believe.

Otherwise known as Rohacell (PMI) foam, this is a comparitively expensive white coloured foam.

It apparently does cut with a hot

wire like polystyrene foam although it is often cut with a knife or saw. It is

available in ready cut sheets at 1 mm, 2, 3, 4.... up to 65 mm thick and more. Modelling applications require 1 or 2

mm thick sheets. Its superior

compressive strength over PS foams means that it's ideally suited

for sandwich construction. Modern moulded models (especially

tailplanes) may use Rohacell as the sandwich between lightweight

(40 -70gsm glass or 100gsm carbon) plies of reinforcement cloth.

It can be cut and sanded easily and is not subject to attack by

most solvents (styrene, acetone, MEK, etc). Rohacell is made by

Röhm of Germany as is classified as Rohacell 31, 51, 71, 110,

170, 190, the numbers denoting it's density in kg/cu.m. We would

use the 51 type for modelling. UK suppliers are EMK plastics I believe.

POLYVINYLCHLORIDE

FOAM

PVC rigid foams are rarely

used in modelling but full size gliders sometimes use it. Trade

names are Termanto, Conticell, Divinycell. These cannot be hot

wire cut easily but must be sawn to size, they are also used as

sandwich materials. They are yellowish brown in colour. Densities

range from 30 to 400 kg/cu.m. Divinycell Webpage

POLYURETHANE

FOAM

We're more likely to see

polyurethane foam from an aerosol can but it's also available in

sheets as a sandwich material. It has few uses in modelling but I

have heard of the aerosol foam used for repairing broken fuselage

booms.

POLYPROPYLENE

FOAM (EPP)

This is the latest foam on

the modelling scene. In the US it comes under the brand name of

Eperan 2, the bead precursor for the foam (Neopolen P) is made by

BASF and is expanded in a low pressure steam chamber without

using blowing agents. In the jargon it's called a closed-cell

thermoplastic olefinic foam material. Nowadays it's used for

wings and fuselages for Combat flying although was originally

developed for use by the car (automotive) industry for impact

absorption (i.e. bumpers, dashes, etc). EPP is a beaded foam

which has a memory; that is to say that it returns to its shape

after being distorted. It is a white coloured foam with a waxy

feel and appearance and really needs to be sprayed with 3M

adhesive before applying fibreglass reinforced tape and/or

plastic film. It can be cut with a hot wire, though not as well

as PS foams. I hear tell some cut it with a flexible wire saw

too. As far as I know it comes in two standard grades, 1.3 lb and

1.9 lb per cubic foot. The lighter version is generally used for

models.

EPP FOAM LINK:

http://epp540.com/

POLYETHYLENE

FOAM (Ethafoam)

Polyethylene foam is similar

to polypropylene foam and is made by the DOW Chemical company. As

far as I know two grades are available: Ethafoam Nova and

Ethafoam Select. They are low-density polyethylene foam products.

For more info: http://www.dow.com/ethafoam

NOMEX

HONEYCOMB

Nomex is not a foam but since it is used as a

sandwich material in full size (and can be used for models) I

include it here. It's made by DuPont and is really a sort of

expanded Kevlar paper. Layers of this paper material are laid one

on top of the other with lines of adhesive. Each layer has the

adhesive lines in a different place. When the adhesive has set

and the layers are expanded the honeycomb is formed. It is then

sawn into sheets. Available in 2 mm sheets upwards for modelling.

Once again a very expensive material and, although difficult to

use, my brother did make a set of moulded wings using it as the

sandwich material. I sometimes use it between two plies of carbon

cloth as a lightweight wood substitute for ply servo trays and

the like. Even though Nomex is mostly air, it still comes in at

29 kg/cu.m.

Nomex is not a foam but since it is used as a

sandwich material in full size (and can be used for models) I

include it here. It's made by DuPont and is really a sort of

expanded Kevlar paper. Layers of this paper material are laid one

on top of the other with lines of adhesive. Each layer has the

adhesive lines in a different place. When the adhesive has set

and the layers are expanded the honeycomb is formed. It is then

sawn into sheets. Available in 2 mm sheets upwards for modelling.

Once again a very expensive material and, although difficult to

use, my brother did make a set of moulded wings using it as the

sandwich material. I sometimes use it between two plies of carbon

cloth as a lightweight wood substitute for ply servo trays and

the like. Even though Nomex is mostly air, it still comes in at

29 kg/cu.m.

If you're looking for foam

suppliers a good place to start is the Yellow Pages under

Insulation. In the UK, Pink Foam came to me via LinPac and Blue

Foam through Sheffield Insulations. Rohacell made by Röhm in

Germany (www.roehm.com)

used to be available here but the company stocking it in the UK

ceased trading. De-Q-cell comes from Bacuplast in Germany and

Nomex is available form R&G Flüssigkunststoff, also in

Germany.

Following on from my short description of the

fabrics available to modellers we now switch our attention to

foam. Foam is used in two ways; either for the cores material in

wood veneered or glass vacuum bagged wings or as the sandwich

material for the skins of hollow moulded wings. We've all come

across white and blue foam but there are some other foams we

could look at...

Following on from my short description of the

fabrics available to modellers we now switch our attention to

foam. Foam is used in two ways; either for the cores material in

wood veneered or glass vacuum bagged wings or as the sandwich

material for the skins of hollow moulded wings. We've all come

across white and blue foam but there are some other foams we

could look at... One such PS foam is De-Q-cell found in Germany

which has a sort of crystalline appearance when you look at it. I

haven't seen it for sale here in the UK but it maybe available

from Windsurf board manufacturers, I don't know. It comes in 3

weights: 17, 30 and 40 kg/cu.m.

One such PS foam is De-Q-cell found in Germany

which has a sort of crystalline appearance when you look at it. I

haven't seen it for sale here in the UK but it maybe available

from Windsurf board manufacturers, I don't know. It comes in 3

weights: 17, 30 and 40 kg/cu.m.

Nomex is not a foam but since it is used as a

sandwich material in full size (and can be used for models) I

include it here. It's made by DuPont and is really a sort of

expanded Kevlar paper. Layers of this paper material are laid one

on top of the other with lines of adhesive. Each layer has the

adhesive lines in a different place. When the adhesive has set

and the layers are expanded the honeycomb is formed. It is then

sawn into sheets. Available in 2 mm sheets upwards for modelling.

Once again a very expensive material and, although difficult to

use, my brother did make a set of moulded wings using it as the

sandwich material. I sometimes use it between two plies of carbon

cloth as a lightweight wood substitute for ply servo trays and

the like. Even though Nomex is mostly air, it still comes in at

29 kg/cu.m.

Nomex is not a foam but since it is used as a

sandwich material in full size (and can be used for models) I

include it here. It's made by DuPont and is really a sort of

expanded Kevlar paper. Layers of this paper material are laid one

on top of the other with lines of adhesive. Each layer has the

adhesive lines in a different place. When the adhesive has set

and the layers are expanded the honeycomb is formed. It is then

sawn into sheets. Available in 2 mm sheets upwards for modelling.

Once again a very expensive material and, although difficult to

use, my brother did make a set of moulded wings using it as the

sandwich material. I sometimes use it between two plies of carbon

cloth as a lightweight wood substitute for ply servo trays and

the like. Even though Nomex is mostly air, it still comes in at

29 kg/cu.m.