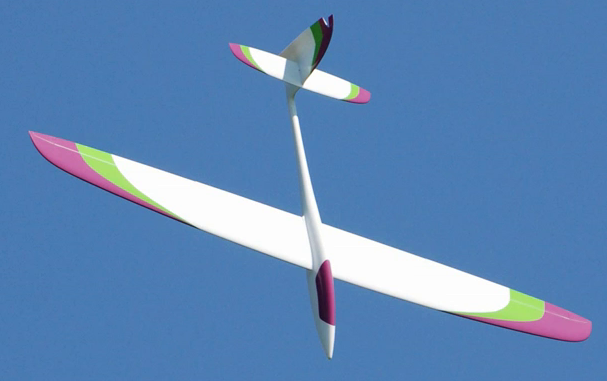

Raptor Aerobatic Model

A Keith Groombridge Design Available On Special Order from BAUDIS

|

||

|

|

|

|

I now have a new aerobatic model. This is the latest version of my tired old Kinetic, which I love, featured elsewhere on these WebPages. My Raptor came with six servos and pushrods fully installed by Baudismodel.com. They are quality MKS high torque, high voltage servos and were fitted perfectly. All I had to do was fit a receiver and battery and balance. I know I would have personally struggled putting the complicated bellcrank assembly and LDS wing (left) and flap (right) servos in the wings. I took a few pictures of my new orange and blue model. The model is made of carbon fibre except the area around the canopy which is bereft of this RF hating stuff so hopefully my FrSky 2.4Ghz RX8R Pro receiver should function well, otherwise it will be 868MHz, we'll see. The paint finish is as good as it gets, in this case orange with a two-shade blue tip decoration (this may change); the underside of the wings is natural carbon with an orange stripe. The fuselage seam line is fine and the fuselage halves look as though they were joined wet with tape. The ailerons and rudder are ready hinged I assume with Kevlar and or Peel-Ply, I don't really know. Overall a very well made model.

The wing servos are screwed into ply plates fixed in the wings so they should come out if/when servo gears are damaged. The LDS looks to be 'home-made' by Baudis (i.e. not proprietary) with aluminium pushrods. Like I said I didn't install them. The LDS horn exits (right) are close tolerance, very nice, leaving only the tiniest of gaps. Nothing shows of the aileron assemblies under the wing. I reckon the servos were installed with 'offsets' of 1300ms (ailerons) and 1800ms (flaps) rather than the normal centres of 1500ms that FrSky uses. This is to get the up/down movements required for the wing surfaces. (Remember raking servo and aileron horns forward and back etc.) The wing dowel is a 'floating' square carbon tube with a foam infill and shear web weighing in at some 80g. (Floating = very loose fit)

I'm not a fan of rudders hinged on one side with a wiper on the other as the servo pushes the rudder sideways against the Kevlar hinge which will eventually weaken. I much prefer pull-pull wires for a rudder but this is how it came. My fuselage came with the servos and carbon pushrods in place and no carbon around the canopy; [sic] 2.4 safe. All I had to do was to put in a receiver and battery. The fuselage, btw, contains internal ply bulkheads along its length. All six servos are HV (high voltage) variants so they will run on a 2S Li-Po or 2S Li-Ion battery at a nominal 7.4v. I chose to use 2 x18650 Li-Ion cells which I made into a pack with a balance plug; but buying any 18650 cells is a nightmare. These came in their own boxes! |

||

|

|

After reading some horror

stories about dodgy cells I settled for a pair of LG

HG2

Brown Li-Ion INR 18650

3000mAh cells. These

are made in Korea I believe but beware because so many 18650 cells are

just (Chinese) fakes and have nowhere near their stated capacities. I chose an electronic, magnetic switch

from T9 but another warning... make

sure these are fixed in place so they cannot move, present day

servos have strong magnets and can actually switch of the power

to your model if they get loose and get too close to a servo

during manoeuvres; I

used the (removable) rubbery UHU Por to glue it in place.

Naturally enough I had to add noseweight to balance the model, I think it was about 130g but I erred on the low side because you can't remove it once it's glued in. I cast a small piece of lead (~80g) in a Plaster of Paris mould to fit snugly right in the nose and then added some extra lead shot there with epoxy to make up the weight. As for the CG, well this is debateable, designer Keith reckons on 96mm from the leading edge but I had my old Kinetic at 102mm. |

|

|

|

|

|

| Surface movements depend on your own

preference but helpfully, designer Keith gives a sheet with

his recommended numbers on it. I generally get as much movement as possible

then decide later how much to change. I sometimes use a 20% or 30% differential

as well. I usually have three modes for general flying, normal,

thermal flap and reflex flap (all with elevator compensation). I

don't use the reflex very much. I also have three switched

flight modes: This gives me nine combinations... plenty for me, I do not use in-flight global variables or in-flight variable camber.

|

Model Specifics

|

|

|

So, this is not a cheap nor commonplace model, it will be very, very expensive with six MKS factory fitted servos, brass ballast, custom wing bags and delivery. |

||

|

|

||

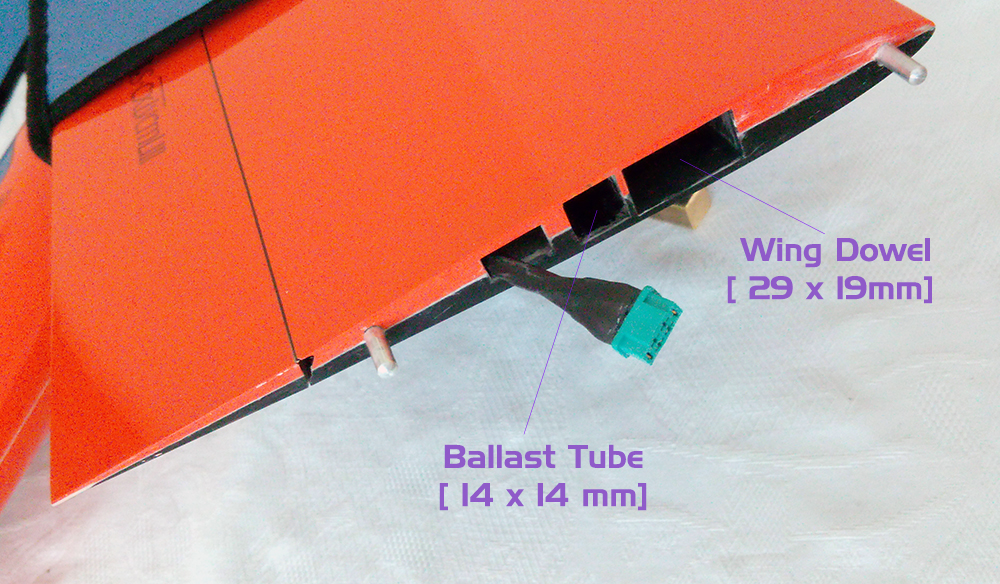

The

wings have ballast tubes which take 3 + 3 brass pieces 14mm

square, you could always replace these with heavier Lead or even

Tungsten but for an aerobatic soarer 500g is ample just giving

the extra bit of climb out in stall turns and extra momentum in

strong slope or thermal lift. In my case Baudis

put in the wiring loom i.e. a green Multiplex plug with

blue Graupner /Futaba/JR style servo receiver plugs. I got the

ready made super wing bags as well.

The

wings have ballast tubes which take 3 + 3 brass pieces 14mm

square, you could always replace these with heavier Lead or even

Tungsten but for an aerobatic soarer 500g is ample just giving

the extra bit of climb out in stall turns and extra momentum in

strong slope or thermal lift. In my case Baudis

put in the wiring loom i.e. a green Multiplex plug with

blue Graupner /Futaba/JR style servo receiver plugs. I got the

ready made super wing bags as well.